Several decoration methods are available in the print-on-demand apparel industry, but the most popular is the direct-to-garment (DTG) printing.

It wasn’t always that way, though. In fact, when DTG was first invented several decades ago, it was notoriously low-quality and imprecise. However, the method has been improved and refined over the years.

In fact, today’s direct-to-garment technology is the gold standard for the print-on-demand industry.

But what is DTG printing, exactly? What are the alternatives? And what makes DTG the standard-setter? Here’s everything you need to know before launching your customized apparel business.

Trivia

DTG's Origins

Direct-to-Garment Printing: Table of Content

Direct-to-Garment Printing vs. Screen Printing

Direct-to-garment printing—alternatively “direct-to-fabric printing”—involves ink spraying directly onto a garment.

The ink can then soak into the fibers of the garment. It’s basically the same concept as printing directly onto paper, except instead of a paper surface, the product is a T-shirt, sweatshirt, or fanny pack.

The other main option for printing customized apparel is screen printing. This method pushes ink through a mesh screen, or stencil, onto fabric. As such, the ink does not soak into the cloth but lays on top of it.

Which Method is Right for Your Print on Demand Business?

While both printing methods have their advantages, there are several reasons why DTG has become the go-to as the industry standard.

For one thing, there’s the matter of setup time. Almost no setup time is required for direct-to-fabric printing, which means it’s equally efficient for bulk orders or one-offs. By contrast, preparing and setting up the stencil for screen printing can be very time-consuming. For this reason, screen printing is primarily recommended for more oversized orders.

There are also issues of quality. Screen printing can work well for basic shapes, but it doesn’t offer the same level of detail you can get from a DTG print. The reason for this is simple: Creating a highly intricate and precise stencil takes a lot of time.

Something else to be aware of: With screen printing, each color is sprayed on separately. Because of this, screen printing is mainly recommended when working with a limited color palette. The direct-to-garment printer makes printing intricate designs much more accessible, capturing vivid details and working with a broader palette of hues.

In addition, many print-on-demand sellers and customized apparel companies are increasingly mindful of environmental issues. DTG printing is more sustainable than screen printing because you can print everything to order. By contrast, screen printing usually means working in bulk, which can result in leftover or unsold wares being dumped in a landfill somewhere.

The bottom line: Direct-to-garment printing is the chosen option for most print-on-demand sellers, both from a business standpoint and a social responsibility standpoint.

Direct-to-Garment (DTG) vs. Direct-to-Film (DTF)

How Gooten Ensures DTG Quality

The direct-to-garment technology has improved by leaps and bounds over the past few years. And Gooten is at the forefront. We’ve developed print-on-demand policies to ensure the highest quality control standards, allowing our print-on-demand partners to choose DTG confidently.

We support our partners by providing ample information about how different designs will look when they come out of the DTG printing process.

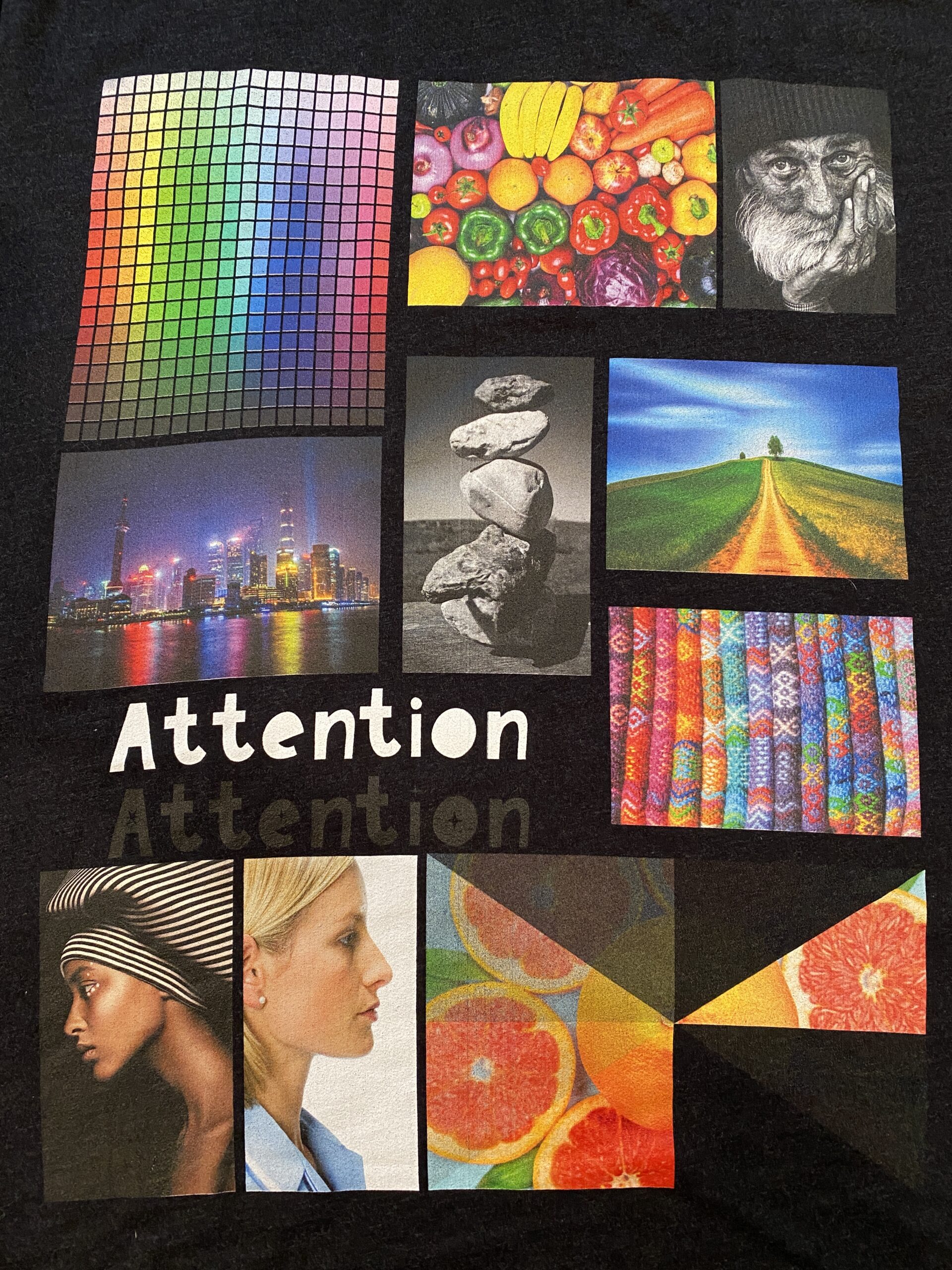

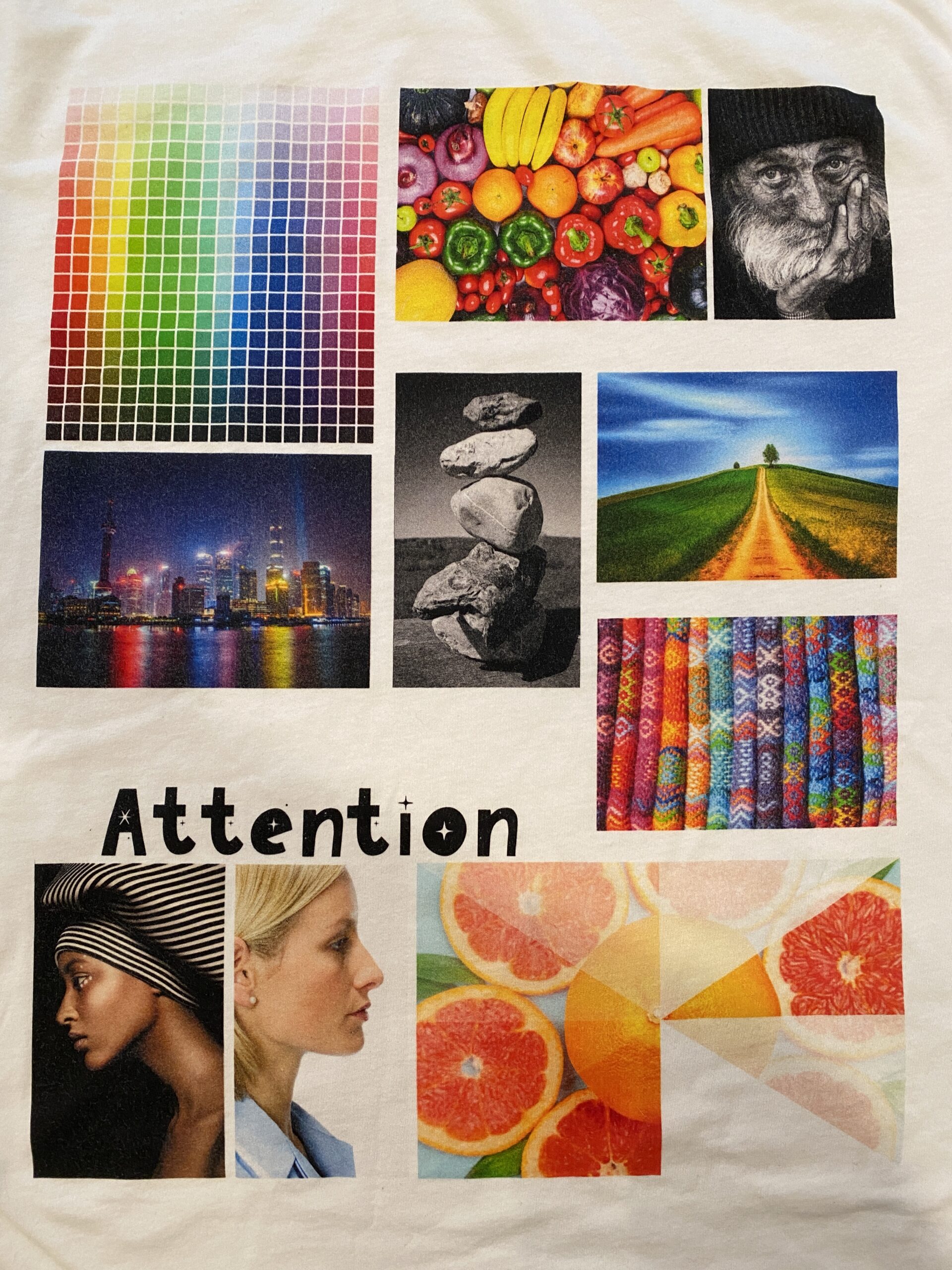

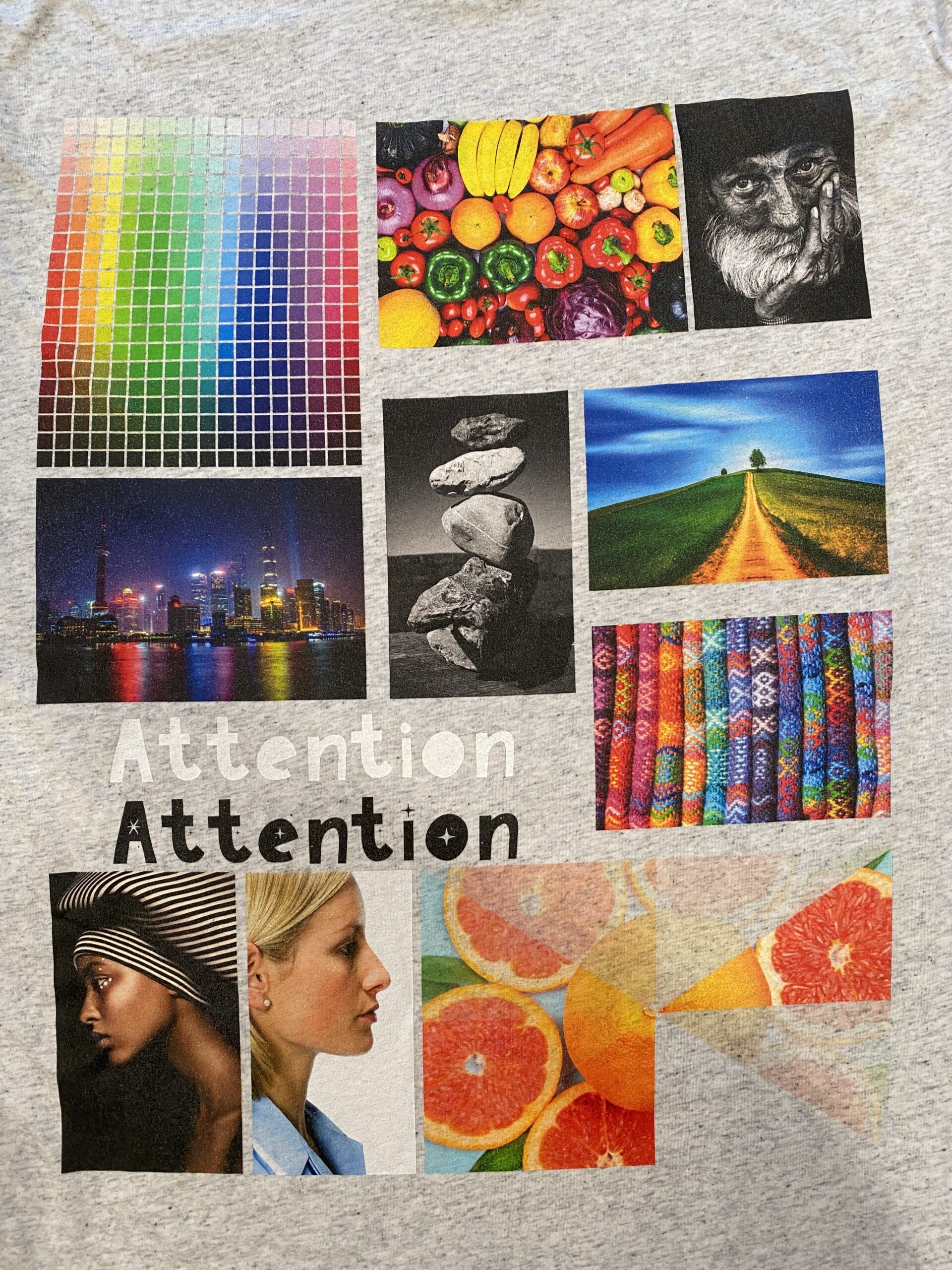

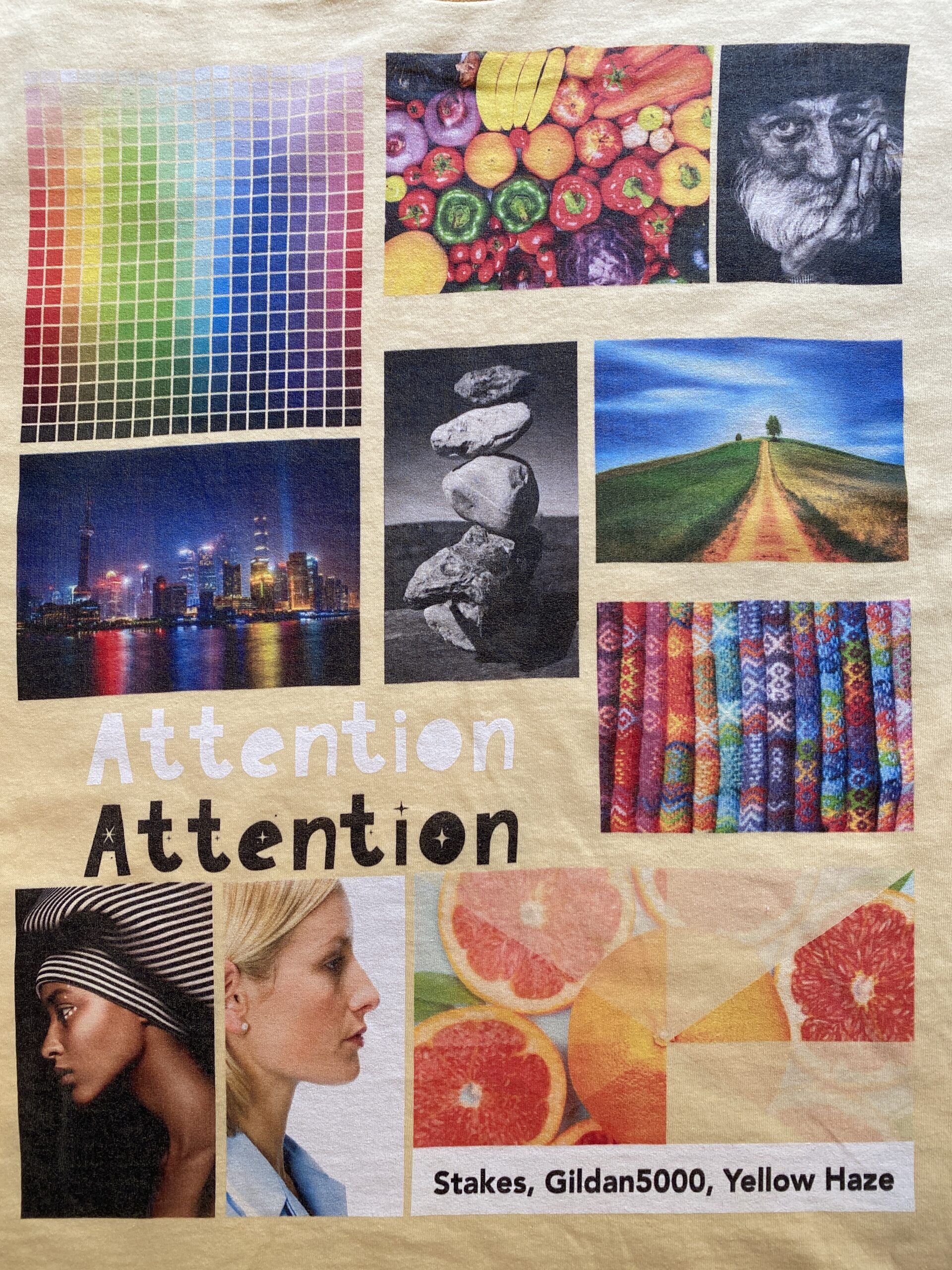

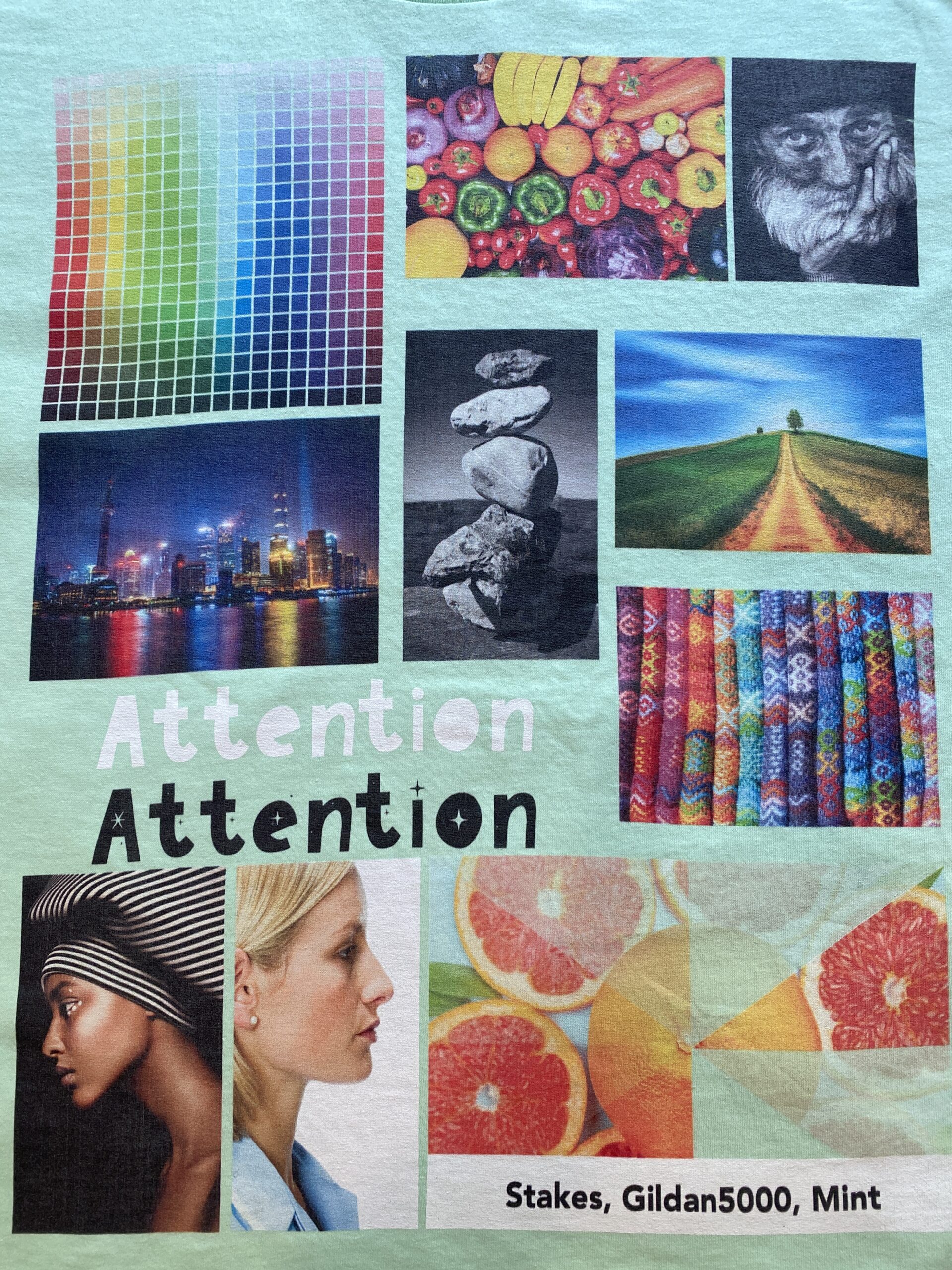

Below, we’ve created a test digital image that features various design elements, which are then printed on black, white, and blended shirts so that you can understand how to create designs specifically for DTG shirts and other DTG clothing.

This digital image features multiple design elements:

- Photography (both full color and B&W)

- Vibrant color swatches

- Flesh tones

- Transparent images

To see how a design on your screen can look on various fabrics and colors, we printed the above method on 5 of our most popular custom T-shirts:

- Test 1: Bella + Canvas 3001, Black, 100% Cotton

- Test 2: Bella + Canvas 3001, White, 100% Cotton

- Test 3: Bella + Canvas 3413C, Heather Grey, TriBlend

- Test 4: Gildan 5000, Yellow Haze, 100% Cotton

- Test 5: Gildan 5000, Mint, 100% Cotton

Bella + Canvas 3001: Unleashing the Ultimate 100+ Color Chart

Bella + Canvas 3001

Bella + Canvas 3001

Bella + Canvas 3413C

Gildan 5000

Gildan 5000

What To Keep in Mind When Designing for DTG Clothing

As the above test images showcase, the same design can slightly vary on different fabrics and shirt colors.

Here are some essential design notes to remember when creating images specifically for direct-to-garment apparel products.

Color Vibrancy Varies by Fabric

- As you can see with Test #1 (Bella + Canvas 3001, Black), bright or vibrant colors tend to be muted, so you may want to increase the saturation in your design for increased vibrancy when printing on dark colors.

- Bright or vibrant colors are more faithful to the original artwork for white garments showcased in Test #2 (Bella + Canvas 3001, White). It won’t be easy to match the colors exactly to what’s on your screen, but it will be closest with white fabric and garments that are 100% cotton.

- When printing on garments that are not white or black, the garment colors can show through your printed images. This is displayed with the Yellow Haze and Mint Gildan garments, which are both 100%. You can see some fabric colors peeking through the images when comparing them to their black-and-white counterparts.

- When designing for DTG, remember that the same image may only be ideal for some garment colors or materials. You may need to customize each design to meet your expected output.

Try to Avoid Transparent Images

- The image of the orange slice wedges showcases opacity at varying amounts. From the top right, moving clockwise, it is 30%, 100%, 20%, 0%, 100%, 85%, 75%, and 40%. As you can see, the image is barely visible at 40% opacity and almost unrecognizable at 30% and below. That’s why we strongly recommend avoiding transparency in your designs.

- When using Transparencies in your design, the DTG printers try to place tiny droplets of ink on small droplets of white under the base. The output will rarely meet your expectations, and depending on the color of the garment you’ve selected, they may not show up at all. If you must use them, we recommend testing your design before going live with the product, or instead, try using halftone gradients.

Be Mindful of Neon Colors

- This is another element to be careful of in your apparel designs. Most DTG equipment uses prints in the CMYK color space, which do not encompass neon colors. The direct-to-garment printer will find the closest possible color, but it won’t be a 100% match.

Choose Gooten for Custom Apparel

Looking for the highest standards of quality and efficiency with your print-on-demand apparel? Choose the direct-to-garment printing method. And specifically, choose the Gooten approach.

We’d love to tell you more about our exacting standards for printing customized apparel with the DTG method and to give you our complete quality control guide. To start a conversation about print-on-demand methods, contact our team of eCommerce and DTG experts today!

Editor’s note: This post was originally published in August 2022 and has been updated for freshness and comprehensiveness.